Bespoke Access Platforms

Bespoke access platforms

Founded in 1993, Semmco is an industry-leading access equipment manufacturer delivering innovative solutions worldwide for commercial and business aviation, aircraft engine manufacture and maintenance, helicopters, rail and vehicle access. We pride ourselves in our ability to provide bespoke and standard access platforms, that can be fixed in situ or mobile, for different industry requirements and customer applications.

We understand that some of our customers have requirements specific to their products or their environment and so we are able to develop bespoke solutions. Our years of experience and team of talented design engineers, mean we are able to work with our customers designing access solutions to meet their specific needs. We provide this service for our aviation and rail customers particularly.

- Fixed and mobile docking solutions for aircraft and engine maintenance

- Fixed and mobile docking solution for helicopters

- Gantry systems for trains

You are currently filtering to show products RESET

Variable Height Helicopter Main Rotor Access Platform

Part No: 812.100.09/10

The Variable Height Helicopter Main Rotor Access Platform is designed to provide safe and variable height access, in the hangar or on the ramp, to the helicopter's rotor.

Double Sided Rail Roof Access Maintenance Platform

Part No: Bespoke product

The double sided rail roof access maintenance platform can be adapted and built to fit your individual rail depot requirements.The height required is invariably different across depots so we can simply

Fixed Height Helicopter Side Access Platform

Part No: 812.005.08

The Fixed Height Helicopter Side Access Platform is designed to provide safe and easy access to the helicopter's engine and/or gearbox and the platform can be used in the hangar or on the ramp.

Variable Height Helicopter Tail Rotor & Main Engine Access Platform LH & RH

Part No: 812.100.13/14

The Variable Height Helicopter Tail Rotor and Main Engine Access Platform is designed to be used as a pair of platforms (LH & RH) to provide safe and easy access either in the hangar or on the ramp.

Helicopter Mobile Access Platform

Part No: 812.007.01

Semmco produces an innovative range of fixed and variable height Helicopter Mobile Access Platforms, designed to provide a safe, stable working area with maximum safety for personnel.

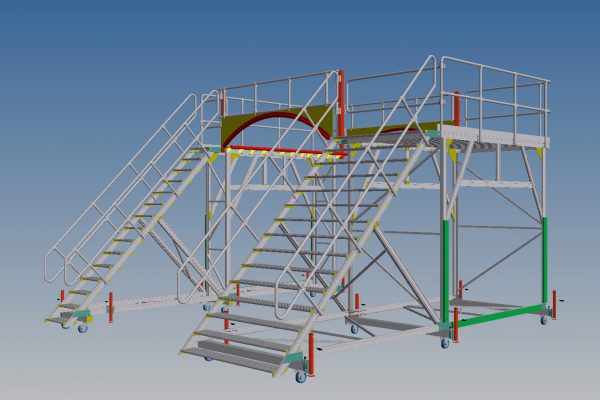

Hercules Maintenance Access Platform

Part No: Bespoke product

This Maintenance Access Platform is for use in the hangar. Constructed from lightweight, compact and variable high grade aluminium sections and corresponding joints and components, the platform provides

Vehicle Roof Platforms

Part No: Bespoke product

A comprehensive range of fixed and mobile roof access solutions, with a range of variable steps/ladders to suit customer installations.Constructed from lightweight aluminium, providing stable and rigid

Typhoon Maintenance Access Platform

Part No: Bespoke product

This Typhoon Maintenance Access Platform provides easy access to cockpit and installation points of both single seater and two seater aircraft.The height of the platform is easily adjusted using the hydraulic

Nose to Tail Docking Systems

Part No: Bespoke product

Nose docking solutions, fixed or mobile, manufactured from high grade lightweight aluminium with wide and narrow working platforms, fixed or sliding finger nose profiles and multi aircraft type functionality.

About our Bespoke access platforms

Some customers have specific requirements where bespoke access systems need to be developed. In these circumstances we work closely with our customers to initially understand their requirements and then develop a bespoke solution to meet their needs.

From Concept to Completion

Our experienced design team will produce a concept to discuss with the customer to ensure that the design will meet all the requirements and be as simple to produce and install as possible. This can take some time but a thorough and considered process at the beginning will ensure that the finished product is perfect!

Once the concept has been approved by the customer, the design process is completed and the product is manufactured. When the product is complete we arrange for delivery and then our Service Engineers install and commission the equipment.

Depending on the nature of the project, this entire process can take up to 24 weeks from the initial discussions and so time planning is critical if the product is required for a specific purpose.

Learn more about our Bespoke Concept, Design and Production service here.

FAQs

How do we discuss a bespoke solution with Semmco?

Please contact us either via our website or call the numbers listed on our contacts page and we can arrange for one of our Technical Sales Engineers to have an initial discussion with you over the phone. We can then arrange for a face to face visit, at your site or a video conference call (depending on your location) to discuss your requirements further.

How does your bespoke process work?

- We will have initial discussions with you to ascertain your requirements and gather as much information as possible so that we can develop some concept drawings of possible solutions.

- Once a concept is approved we will ask you to sign it off before any detailed design work is carried out.

- Our Design Engineers will develop detailed drawings for your approval and sign off.

- Once the detailed drawings are approved we will input the project into our purchasing and production phases.

How long does a bespoke product take to be designed, manufactured and delivered?

We usually recommend 22-24 weeks lead time from initial discussions but this time frame is driven by the nature and complexity of the project. We will provide a clearer time frame once we have sight of the project.