Case Studies

How Semmco products help maintenance teams around the world to do their jobs efficiently and safely

How Semmco uses intelligent engineering to help solve their clients' problems

Semmco is an innovative engineering company with offices in the UK, USA & UAE delivering to an extensive list of global clients.

Not only do we develop new and exciting products for a range of industries, our design team works closely with customers to find solutions to their individual issues.

Below are some of the case studies for projects we have worked on, and products we have developed at Semmco.

If you have a project or current challenge for your engineers that you would like to discuss with our design team to see how they could help, please get in touch by email to sales@semmco.com or call one of our offices:

UK +44 (0)1483 757200 USA +1 682 252 4148 UAE +971 (0) 509 509 104

Semmco worked with Alstom and Arriva TrainCare to develop a double sided roof and door access platform incorporating two off jib cranes. Alstom carries out maintenance work to replace doors and change the HVAC units for Arriva TrainCare. This is an ongoing maintenance requirement, and because of the complexities of the work, specific access, combined with lifting equipment needed to be installed in the Arriva Gateshead facility.

The project was made doubly difficult because of the age of the maintenance facility, its restricted height and curved roof. Alstom and Arriva worked together and appointed Semmco to design, manufacture and install a suitable solution.

Lufthansa Technik Puerto Rico (LTPR) specializes in maintenance, repair and overhaul also known as MRO services. This world-class base maintenance site concentrates on the Airbus A320 range of short and medium-range aircraft. In this MRO site, a variety of in-house docking systems enabled crucial access to the aircraft nose, wings and tail, but an internal improvement drive identified the need for a standardised platform to access the intricate nose avionics area. The new platform had to work within the constraints of the specialist docking systems and be adjustable so that it could still be used when the aircraft was on jacks or wheels. It was also important that the new platform didn’t take up too much space in the hangar – an issue with the previous system.

In 2018 Alstom Trains was awarded the European Railway Traffic Management System (ERTMS) National Implementation Onboard Project in Norway. This project, to be delivered over a six-year period, involves equipping nearly 400 rolling stock vehicles with Alstom’s ERTMS system. Part of the installation work requires engineers to work at height on the train roofs and as Alstom has a strict rule that any working above 50cm is ‘work at height’, it is extremely important to ensure a safe working environment is provided for the engineers at all times. Consequently, Alstom issued a tender for a flexible and movable roof access solution together with a variable side access solution to accommodate the different types and shapes of rolling stock and provide the safe working environment they required.

Find out more

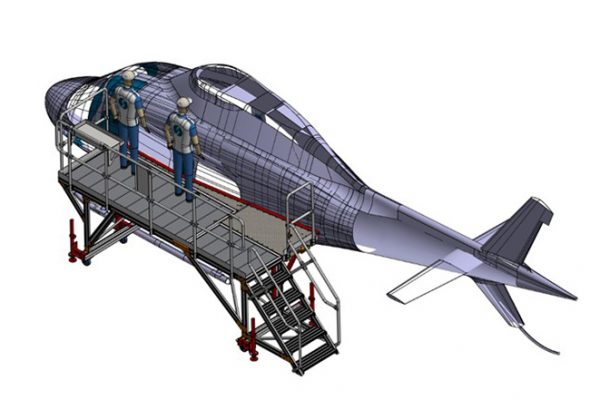

What do you do when a supplier can no longer provide an after-sales service for critical safety equipment? This was a problem for a US helicopter engineering facility that had previously purchased access platforms from a French supplier, recommended by their Italian parent company. Unexpectedly, the supplier was unable to provide regular after-sales support in the US and as this was likely to be troublesome for the helicopter engineering facility, they decided to find a more suitable and reliable ‘local’ supplier. Their requirements had evolved too as they needed an engineering company with expertise in designing and manufacturing helicopter support equipment that could not only supply a quality product but also be capable of managing design change requirements, as well as providing 24/7 after-sales support. They also wanted to purchase equipment that could be easily repaired without the entire product having to be scrapped. To find a suitable supplier, the company issued a tender and after due process, Semmco Inc was appointed.

Variable height refuelling steps can be staged at different heights to accomodate dual fuellng connections quickly and safely.

Find out more

Portable therapy oxygen cylinders, used in the aircraft for passenger assistance during flights, need to be serviced and charged regularly. This operation is made easier with the Semmco Oxygen Charging Rig without adding pressure to turnaround times.

Find out more

When working in a time-critical environment it is vital that aircraft maintenance repairs are carried out safely and efficiently. The Walk Round Nitrogen Charging Kit is designed to provide an easy to use and convenient solution for topping up door assist bottles – critical to aircraft departures.

Find out more

In order to carry out maintenance, engineers must gain access to a variety of equipment such as: passenger displays, telecommunications equipment, air-conditioning units and pantographs. For short periods of time it will also be necessary to maintain locomotive carriage roofs and it is important to minimise the length of time that this equipment is out of service.

Find out more

The Semmco SMART trolley provides customers with a low cost solution for oxygen and nitrogen refilling. The trolley includes safety features to address the issue of manual handling of cylinders along with a collapsable design suitable for cost effective international shipping.

Changing a wheel and brake pack on an aircraft is a testing operation as it involves moving large and heavy wheel and brake pack units along with tooling to the aircraft. The Semmco Wheel & Brake Service Trailer makes this difficult operation much easier.

Find out more

In order to carry out an entry into an aircraft fuel tank, engineers potentially expose themselves to a combination of hazards and threats that need to be adequately controlled before an entry is made.

Find out more"An extremely reliable company who consistently deliver an expected high quality of product on time. Their advice and guidance on some issues saved considerable time in manufacture. "

Hitachi Rail